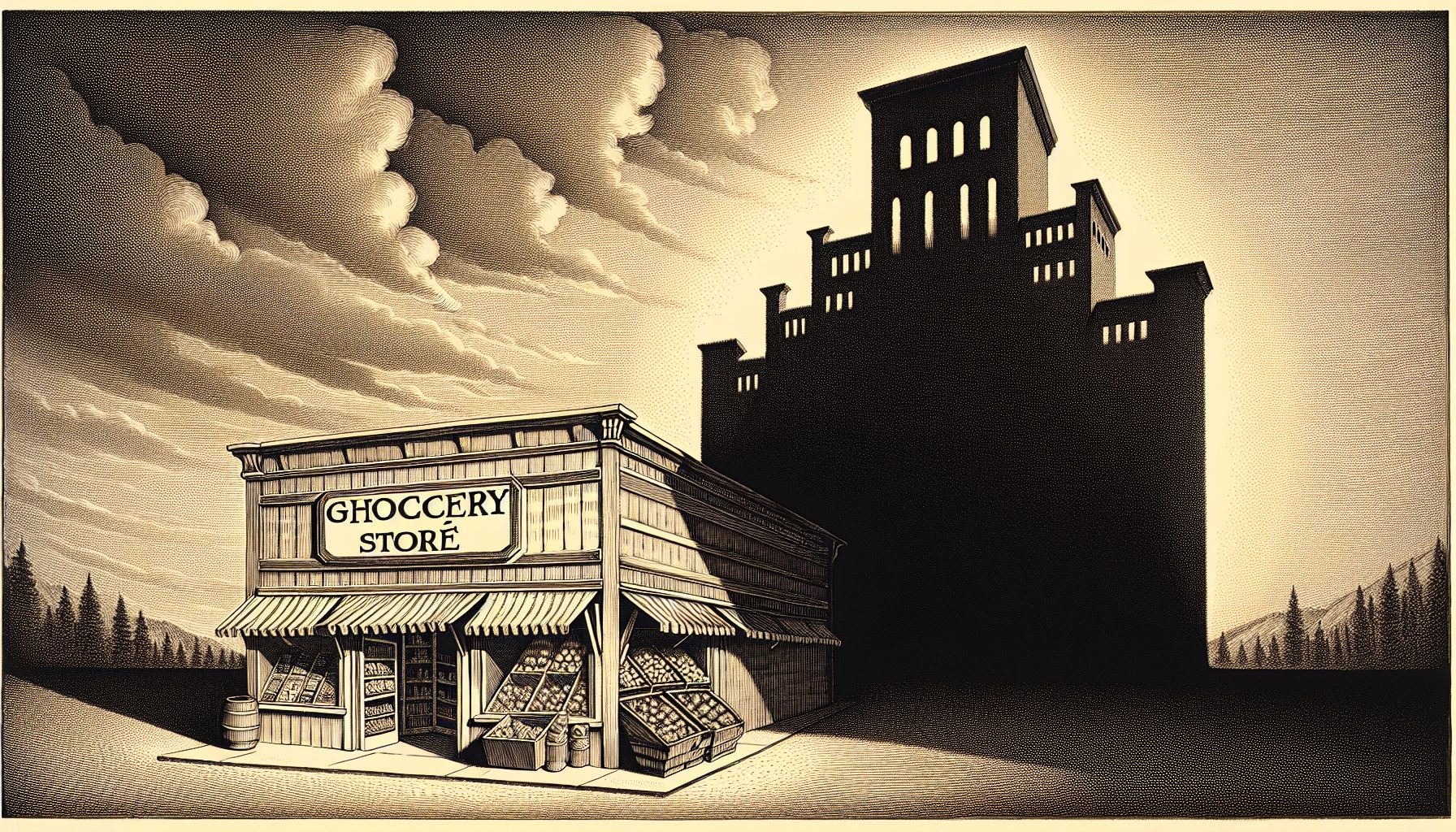

By Acquiring a competitor in 2000, and another in 2005, PerTronix Performance Products amassed a wide-ranging portfolio of automotive exhaust and ignition products.

At the same time, though, the family-run business struggled with disconnected enterprise resource planning systems, with order management, billing and inventory systems spread across three separate facilities in Southern California.

That disparity stalled PerTronix’s ability to meet customer demand, says project manager Steve Reh, who oversees information technology for the San Dimas, Calif.-based company. For example, when customers called in orders, a PerTronix employee in Rancho Dominguez, Calif., would key in the product and check inventory. (The company’s third location is in Riverside, Calif.) But before the product-such as an exhaust header, ignition distributor or muffler-could be shipped, order slips had to be produced in San Dimas and faxed to the office where the order was taken. After that, the sale details had to be re-keyed into yet another office’s accounting and billing system.

"We had no integration between the three locations," says Reh, who reports to the company’s president and CEO, his father, Tom Reh. "Because the system wasn’t across the organization, we had to key everything into the system twice."

That’s just one of the problems PerTronix faced with the siloed setup. On top of that, in late 2004 Hewlett-Packard said it would no longer support its HP 3000 minicomputers, which PerTronix used to run its enterprise resource planning functions.

At that point, PerTronix was running three different ERP systems. The San Dimas headquarters had used GrowthPower, from Mapics (now owned by Infor), for almost 20 years, running on the HP 3000. The Rancho Dominguez office, formerly the location of Ermie Immerso Enterprises, which PerTronix bought in August 2000, ran a terminal-based production planning and inventory monitoring system. And in the Riverside facility, which PerTronix added when it acquired Doug’s Headers in January 2005, the company used a customized Microsoft Access database.

So, Reh’s first order of business in 2005 was to find a new system that would replace those systems and subsequently connect the three facilities. Initially, Reh says he thought the evaluations would lead to a decision within 30 days.

But the process took longer, exposing the 100-employee firm to some of the biggest vendors in the software world and ultimately landing them where they least expected: with an open-source ERP system.